-

Description

The undisputed Queen of all dough sheeter! Thanks to its 10” colour touch screen and to the easy and intuitive programming it will be clear and quick to create, modify and save the programs (up to 100). The stainless-steel structure, with table support mounted on wheels, guarantees the maximum stability and allows to process large quantity of dough for each cycle, making the most of the belts of 700mm of useful width. Unfalling, considering the type of machine, the automatic flour duster and coiler. On a mechanical level, the opening and closing of the cylinders take place through the strong and tested system of oil bath screw, that ensures the maximum precision with any type of dough. The movement of the belts occurs by means of two independent brushless motors, that enable to change the ratio between the inlet and outlet speed of the dough, thus avoiding the wave effect that can form at the inlet, especially with very thin thickness. The quick release of the belts and the easily accessible scrapers help the daily cleaning of the machine. The standard equipment is completed with an USB socket for the backup of the programs and the wi-fi connection particularly useful for the remote connection. -

Video

Video

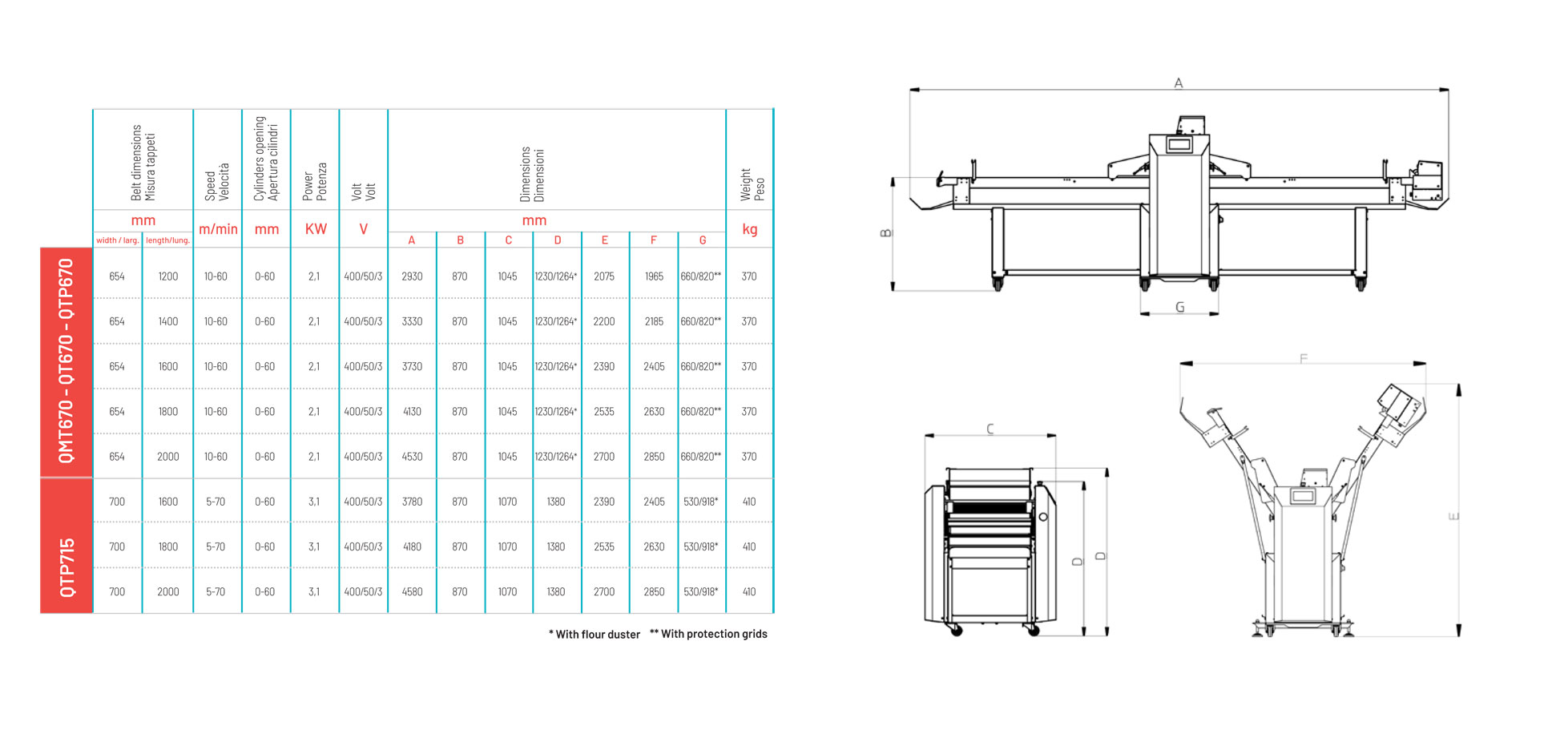

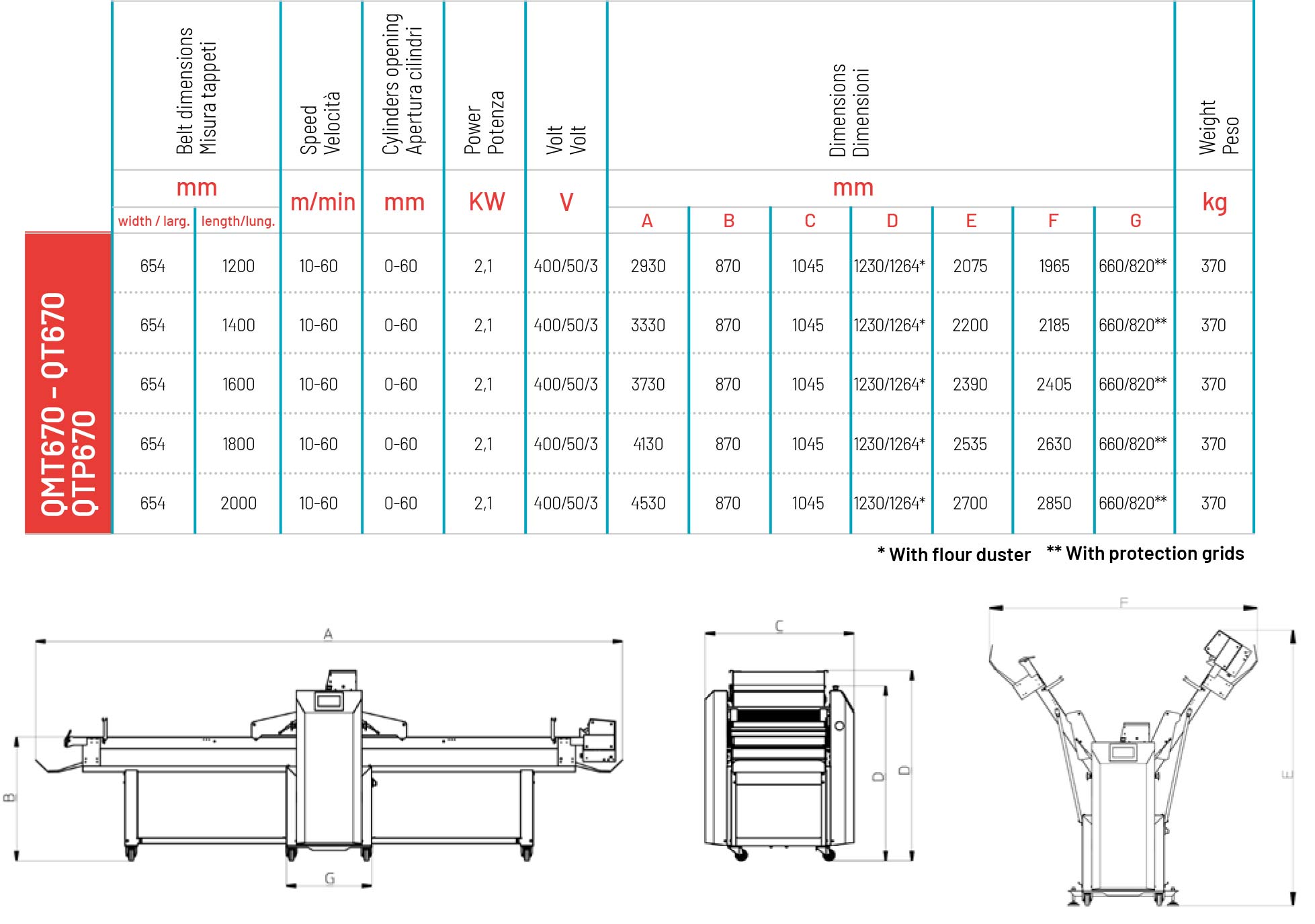

Technical Specifications

Accessories

Description

The undisputed Queen of all dough sheeter! Thanks to its 10” colour touch screen and to the easy and intuitive programming it will be clear and quick to create, modify and save the programs (up to 100). The stainless-steel structure, with table support mounted on wheels, guarantees the maximum stability and allows to process large quantity of dough for each cycle, making the most of the belts of 700mm of useful width. Unfalling, considering the type of machine, the automatic flour duster and coiler. On a mechanical level, the opening and closing of the cylinders take place through the strong and tested system of oil bath screw, that ensures the maximum precision with any type of dough. The movement of the belts occurs by means of two independent brushless motors, that enable to change the ratio between the inlet and outlet speed of the dough, thus avoiding the wave effect that can form at the inlet, especially with very thin thickness. The quick release of the belts and the easily accessible scrapers help the daily cleaning of the machine. The standard equipment is completed with an USB socket for the backup of the programs and the wi-fi connection particularly useful for the remote connection.

Video

Video

Technical Specifications

Video

Technical Specifications

- 1

- 2